There are various reasons for finding a gearbox assembly supplier. You could be a manufacturer of automobiles, machines, or aircraft. That could be any reason, and you might be looking for some information regarding their applications. Here are some pieces of information that might be suitable for you.

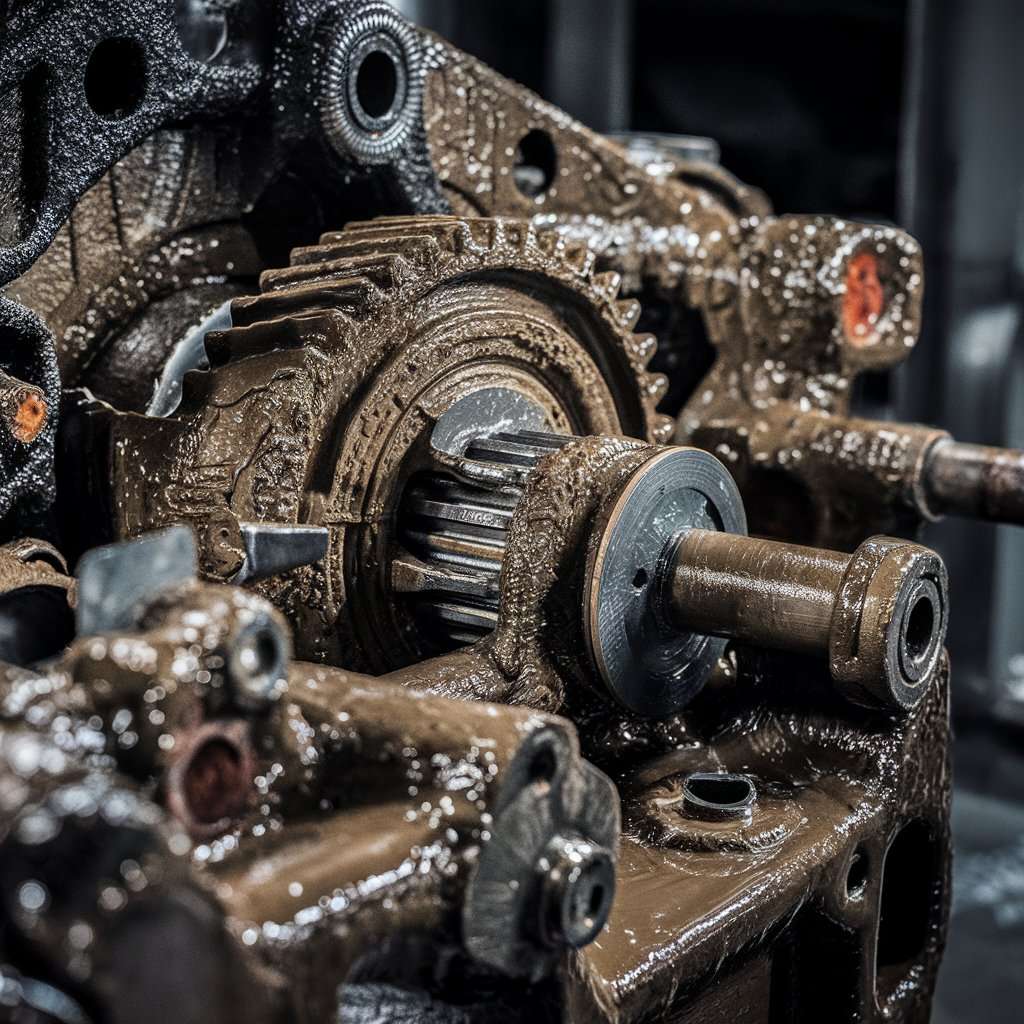

Motor gearbox housings are indispensable protective shields for the intricate gear systems that power industrial automation. These robust enclosures safeguard delicate components from harmful contaminants such as dust, dirt, and moisture, ensuring their longevity and optimal performance. By providing a sturdy structural framework, they maintain precise alignment, which is crucial for smooth and efficient operation. Moreover, these housings significantly reduce noise levels, creating a quieter and more conducive work environment.

These housings are meticulously engineered to withstand demanding industrial conditions, including exposure to extreme temperatures, vibrations, and shock loads. They are often constructed from high-quality materials such as cast iron or aluminum, which offer excellent durability and resistance to corrosion. Additionally, these housings may incorporate advanced sealing technologies to prevent ingress of contaminants and ensure reliable operation in harsh environments.

In the intricate world of robotics, motor gearbox housings often go unnoticed, yet they play a pivotal role in ensuring the smooth and efficient operation of robotic systems. These robust enclosures serve as the first line of defense, safeguarding the delicate gearbox mechanism from potential damage caused by external factors such as collisions, impacts, and environmental contaminants. By protecting these critical components, housing manufacturers extend the operational lifespan of robotic systems, reducing maintenance costs and downtime.

Beyond their protective function, motor gearbox housings also contribute significantly to thermal management. They are designed to facilitate efficient heat dissipation, preventing overheating and ensuring optimal performance, even during prolonged operation under demanding conditions. This is particularly crucial in high-performance robotics applications where heat buildup can compromise the accuracy and reliability of the system.

Moreover, the design of these housings is meticulously engineered to achieve a delicate balance between weight reduction and structural integrity. By minimizing weight, manufacturers can optimize the overall weight and energy consumption of the robotic system. Simultaneously, the housings must maintain sufficient structural rigidity to withstand the rigors of industrial environments, including vibrations, shock loads, and temperature fluctuations.

In conclusion, motor gearbox housings are indispensable components in the field of robotics. By providing robust protection, efficient thermal management, and lightweight design, these enclosures play a vital role in ensuring the reliability, performance, and longevity of robotic systems across various industries.

Motor gearbox housings are indispensable components in the automotive industry, particularly in power steering systems and automatic transmissions. These robust enclosures shield the delicate gearbox components from harsh environmental conditions, including road debris, moisture, and temperature fluctuations. By safeguarding these critical components, the housings contribute to the overall reliability and longevity of the vehicle's drivetrain.

Beyond physical protection, these housings play a significant role in noise reduction. By minimizing the transmission of mechanical vibrations and gear noise, they enhance the overall driving experience, creating a quieter and more comfortable cabin environment. This is particularly important in modern vehicles, where noise levels are a key factor in passenger comfort and vehicle refinement.

The design of these housings is carefully considered to optimize performance and durability. They are often constructed from high-quality materials such as cast iron or aluminum, which offer excellent strength, rigidity, and resistance to corrosion. Additionally, the housings may incorporate advanced sealing technologies to prevent ingress of contaminants and ensure reliable operation in various environmental conditions. By providing a robust and reliable protective enclosure, motor gearbox housings contribute significantly to the overall performance and longevity of automotive drivetrains.

Motor gearbox housings are crucial components in the automotive industry, especially in power steering systems and automatic transmissions. These robust enclosures safeguard delicate gearbox components from harsh environmental factors such as road debris, moisture, and temperature extremes. By shielding these critical components, the housings contribute to the overall reliability and longevity of the vehicle's drivetrain.

Beyond physical protection, these housings play a vital role in noise reduction. By minimizing the transmission of mechanical vibrations and gear noise, they enhance the overall driving experience, creating a quieter and more comfortable cabin environment. This is particularly important in modern vehicles, where noise levels significantly impact passenger comfort and vehicle refinement.

That was all about gearbox assemblies. Hopefully, it might helped you somehow.